Information Details

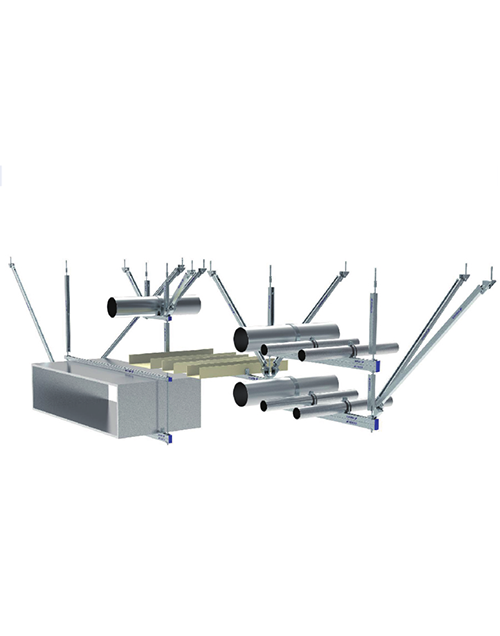

Seismic brackets: Things to note about seismic bracket installation

Release Time:

2021-06-09 16:24

Seismic bracket: When choosing seismic bracket, we should first pay attention to whether the tension and yield point of the bracket are suitable, and the installation requirements of the bracket in different places have some differences. In order to achieve better results in the installation and application of the bracket, we should pay attention to understand the parameters of the bracket. Reasonable bracket parameters can make the application of bracket more convenient and can also meet the environmental requirements, so that the installation and application of bracket can achieve better results. In the process of installing seismic bracket, we should pay attention to the stability of the bracket and pay attention to the material selection of the selected bracket, which has a great influence on the stability of the bracket. In addition, we should have some understanding of the process selection of the support. The bracket made by standard process method can achieve better installation and use effect, and also can avoid the damage caused by environmental influence during the use. The application of seismic brackets has been highly valued by the society and also directly affects the stability of the related equipment during construction. So pay attention to whether the performance is up to standard when choosing the bracket.

Seismic bracket installation specification:

1. No welding or punching is required to install the seismic bracket. It can be directly disassembled, replaced and adjusted, and the disassembled parts and bridges can be reused without causing fearless waste.

2. Seismic bracing has good compatibility and can be shared with many kinds of bridges or coordinated well among many kinds of bridges.

3. Ducts and cable sleeves can be slightly offset longitudinally, but the larger offset cannot exceed 7/1 of the lateral distance. ducts can be slightly offset, but the larger offset cannot exceed 2.5 times of the duct style.

4. In 90 degree vertical and horizontal bending, seismic support position is required, while when other corners are greater than 1/15 of the seismic design distance, seismic support is required in the transverse and longitudinal direction.

5. When the load of horizontal vibration force needs to be calculated, only the larger load weight needs to be calculated without considering other factors.

6. When installing seismic bracing, it is not necessary to limit the response caused by thermal expansion and contraction of pipelines. If the reactions caused by thermal expansion and contraction need to be considered, the selected parts should be considered when choosing the parts for the longitudinal support.

7. The seismic brace used in rigid pipeline cannot be installed in different structural parts or functional parts of the building, otherwise it will cause certain displacement during the earthquake.

Ltd. is mainly engaged in the following products: open bar soft seal gate valve, flange butterfly valve, electric butterfly valve, pneumatic butterfly valve, stainless steel gate valve, stainless steel ball valve, etc. It is a seismic bracket manufacturer with modernized, scientific and diversified production, R&D and sales enterprises of valves, seismic brackets and water treatment equipment. Seismic bracket brand and other supporting complete, from a single product, talent shortage of valve company, step by step steady, relying on the meticulous attitude to quality gradually growing excellent quality, technology first, innovation and pragmatic, integrity management, is our company's business philosophy. We will cooperate with you sincerely with good products, perfect service and reasonable price, and create a brilliant tomorrow of Chinese valve industry together.

抗震支架

Latest News